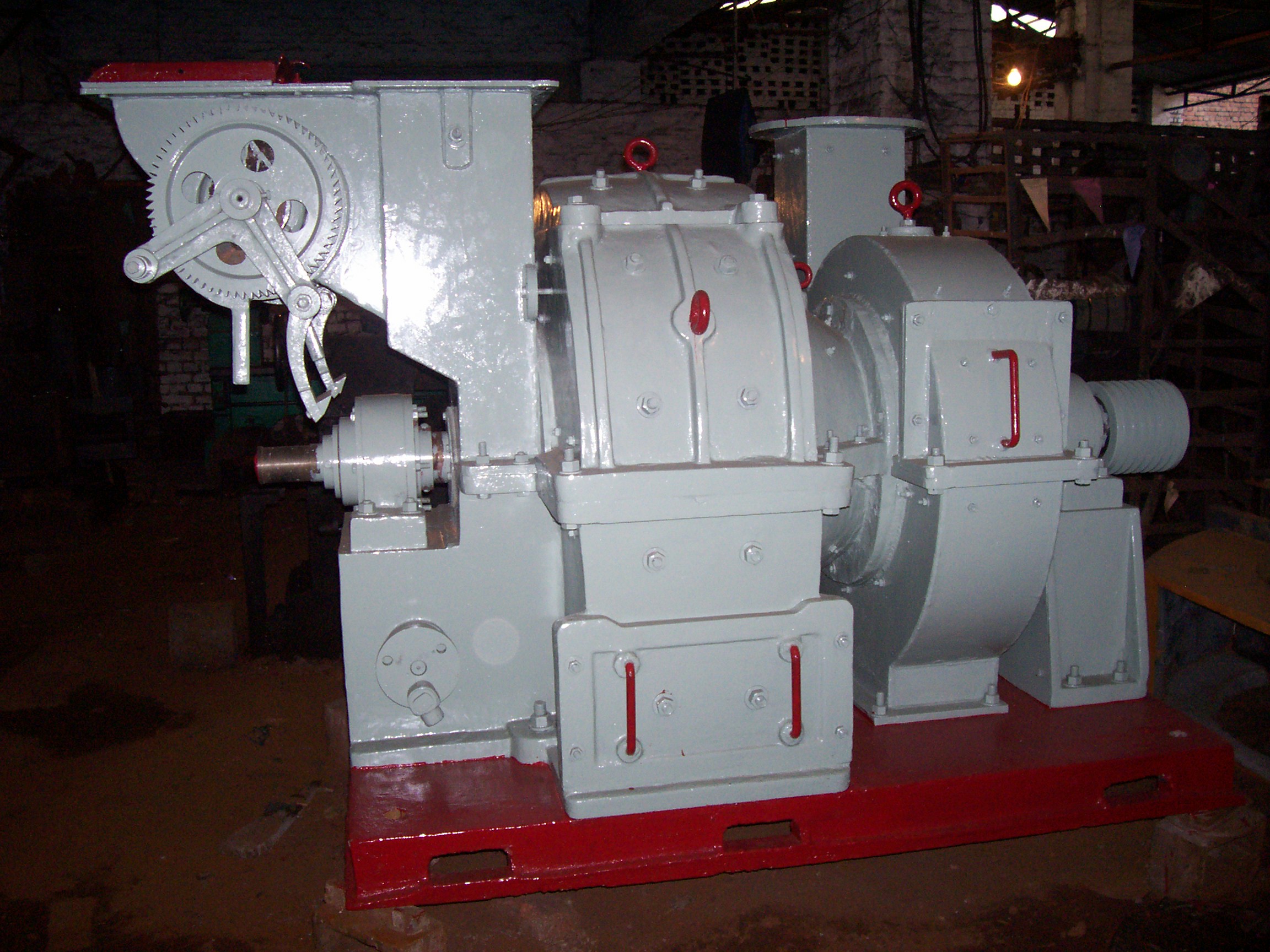

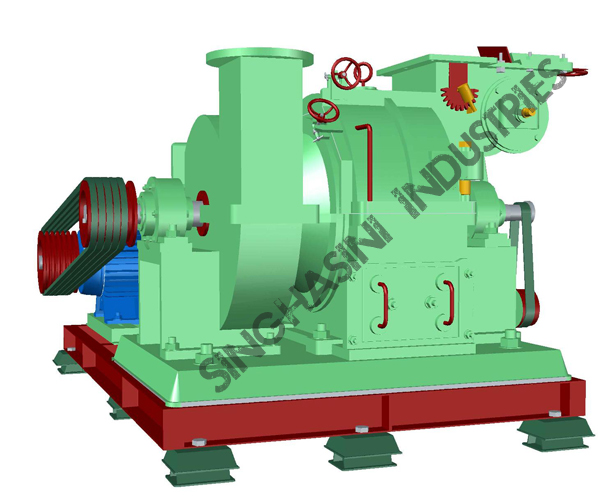

Singhasini Impact Pulveriser are ranked high among Indian manufacturers for more than a quarter century. We pioneered much of the technology in use today for Pulveriser in India and Introduced modifications to suit different application.The result is the Pulveriser which was initialy used for grinding minerals only ,now is being used for grinding variety of materials in various industries.Time to time introduction of existing technology has helped to improve the Pulveriser.The examples are Anti vibration base frame to replace civil foundation; Pulse jet Dust collector to make it environment friendly; Electronic feed controller for better efficiency of mill and safety of motor. Principle Of Operation :Pulveriser is a Hammer Type Grinding mill where the feed material is subjected to repeated blows of hammers, revolving at high speed.The main mill consist of a Star Type Automatic Feeder which receives the material from a hooper and feed it into the grinding chamber , multiple row of hammers revolving at high R.P.M grind the material by repeated blows against fixed liners . Fine particles thus genereted are sucked by a high suction Blower which discharge it into a Cyclone Collector . Fineness of material is controlled by aWhizzer Type Classifier located between Grinding Chamber and Blower. Pulveriser is available in eight different sizes to suit the need of consumer